I am pleased to report that I was able to get the lasts out of these boots today!

After I’ve built the heels to the correct height, I add the rubber heel cap. Next I pull the lasts out so I can do the final heel shaping.

Or… I try very hard to get the lasts out, fail miserably, stop before I exhaust myself too much, spray water down inside the boots, and wait until tomorrow to try again. Putting water on the pegs makes them swell up and hold tighter, but when they dry completely they’ll become brittle and ideally they will break off and allow me to pull the last out. Send me good wishes for tomorrow.

Friday afternoon at my shop I taught a two hour class for ten students and their instructors, from a college costume design course in Oklahoma City. That’s a whole lot of people to try and teach how to cut and skive in a very short time, but they all finished their projects. Each of them made two little patches — one with an overlaid flower and inlaid leaves, and one with an inlaid steer head. I didn’t get pictures because I was too busy, but they all seemed happy when they left. The instructors asked how often I taught classes like this and I had to admit that I do not ever and they must have asked me on a day when I was feeling unusually agreeable.

I’ve attached a photo of the two projects, done by me. I was getting ready to make mine before the class to show as examples, when I realized that both pieces were so simple it would be better to demonstrate them instead. That way, instead of explaining cutting and skiving in words, I could actually show them the techniques as I made the pieces.

I can’t also teach sewing skills in a class that brief so I sewed everyone’s project. I often do all the sewing in a class like that and sewing twenty inlay projects as quickly as I possibly can while they all stand in line waiting is stressful. I tend to imagine that everyone is impatiently waiting, which no one seemed to be. One of them even said they were enjoying watching me sew really fast. They asked if it made me nervous or less accurate to talk or answer questions while sewing, and that was an amusing thought. Sewing is like breathing to me and my brain doesn’t have to be fully engaged with it.

LOL, I just realized that yesterday I was watching a musician sing while beautifully playing a guitar and that looks incredibly difficult to me. But I can sing (or talk) and sew something complex at the same time and it’s easy.

I can’t stop playing with asymmetry. I love a design that isn’t symmetrical but it is balanced, so that’s always my goal.

One more update from my weekend: Every year since 1993, I’ve attended the Boot and Saddlemakers Roundup in Wichita Falls, Texas. An important part of the event is the boot making competition, where we all create our very best work and vie for first place in one of the many divisions. The Master Category is for experienced makers; there aren’t really any guidelines for that category other than you have to be willing to compete against makers who are brave enough to choose it.

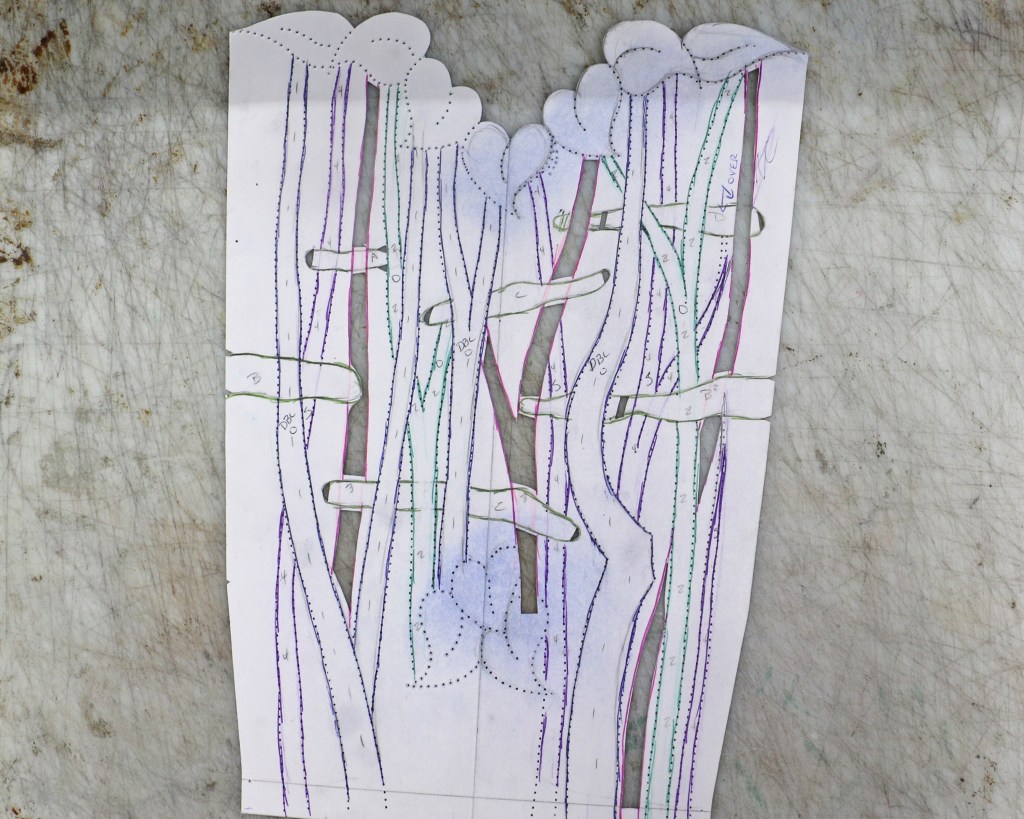

A few years ago I began creating art pieces based on concepts that are difficult to convey with my medium of leather inlay, overlay, and stitching — things like light, shadow, movement, and reflection. I had an idea for conveying depth and in a moment of hubris I decided to do it in boot top form rather than a single art piece. My idea was to do a grove of aspen trees, hoping for the feeling of looking into a forest.

Typically I post process photos as I’m making the boots, but since these were for a competition I decided to not share them to social media at all. So now, all in one post, I will share process and completed photos of the boots that won the Master Category at the Boot and Saddlemakers Roundup. These boots are titled “Rocky Mountain High.”

Several years ago — at least fifteen — I learned about the MacArthur Fellowship Genius Grant and it changed my life. My initial goal was (of course) to win it someday, so I began reading about exactly what the qualifications were: “At the heart of the MacArthur Fellows Program is its aim to identify extraordinarily creative individuals with a track record of excellence in a field of scholarship or area of practice, who demonstrate the ability to impact society in significant and beneficial ways through their pioneering work or the rigor of their contributions.”

I began to think about the type of person I’d need to become in order to qualify. I started my YouTube channel with tips and techniques, and for eight years I consistently filmed videos and added to my channel. I’ve been recognized in other countries by viewers of those videos. Last year I attended a shoe making event in New York City; the event started with a group of shoe makers telling their origin stories, and I was astonished at how many of those stories began with me and my YouTube channel. I began teaching and speaking and writing. Eventually my goal turned into being that person rather than winning the award.

This past weekend, at the Boot and Saddlemakers Roundup in Wichita Falls, Texas, I was honored with a Lifetime Achievement Award. Some of my students and friends and mentors spoke prior to presenting the award, and the beautiful things they said about me indicated that perhaps I’ve achieved my goal. The MacArthur Fellowship jurors are secret and there’s no way to apply or be nominated, so my chances are similar to winning the lottery. But I will always be grateful that I found the award and decided to try and be the sort of artist they’d recognize. The initial goal — to win — was too small. I’m glad I pursued generosity and learning and teaching and growing as an artist, because it made me a winner!

My 2026 cowboy boot calendar has arrived and it’s available for purchase on the website!

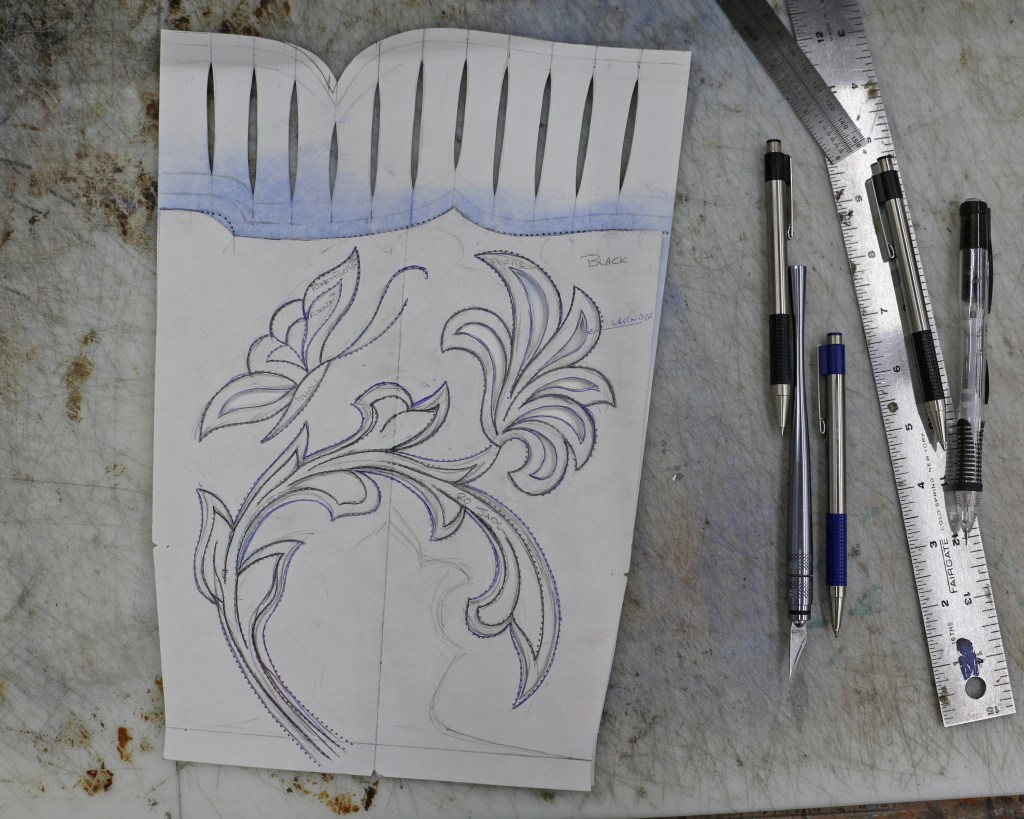

Look what I found in my archives* this morning. I would have sworn to you that I am unable to do boot sketches but evidently at one point I did. This drawing has to be 25 years old and apparently I never went any further than cutting out the top band and saving it with the sketch. It’s very obvious here that my early design preferences and ideas were based entirely on Marty Stuart’s tastes.

*Box of random accumulated stuff

Yesterday I posted a photo with the leather filler in the bottom of the boots. Today, in order, you can see the stitched-in shank, the shank cover (pegged but unsanded), and the final shaped shank cover.

Also costarring my little shoes in every photo.